Green gold: Turning trees into 'biofactories'

Article Highlights

- A team of researchers led by Michigan State University’s Björn Hamberger reports new findings that could help engineer poplar trees to produce high value chemical compounds.

- Producing these compounds could greatly increase the economic viability of poplar trees as a source of biofuel.

- The team specifically explored the production of a chemical known as squalene which is currently harvested from shark livers and widely used in cosmetics and vaccines.

What do poplar trees, sharks, and biofuels have in common?

While it might sound a bit like a riddle, a team led by Michigan State University biochemists has reported exciting findings concerning all three in the quest for cleaner energy.

Appearing in the Plant Biotechnology Journal, the team’s latest paper explores how poplar trees can be engineered to produce a highly valuable chemical that’s commonly obtained from shark livers.

Engineering poplars to produce this chemical would greatly boost their economic viability as an already-promising source of biofuels, as well as help cut back destructive shark harvesting.

“I think this project really highlights how we can use industrial crops in new ways,” said Jake Bibik, first author on the paper and a former doctoral student in the lab of Michigan State researcher Björn Hamberger.

“Using engineered, non-food crops like poplar may provide a more sustainable alternative for generating chemicals typically derived from fossil fuels, or even new specialty chemicals altogether.”

More bang for your buck

On their own, poplars check several boxes needed to be a successful biofuel feedstock.

They grow quickly on land not used for agriculture, and their biomass — the organic material where energy is stored — can be deconstructed and fermented for biofuel production.

One of the biggest challenges comes down to simple economics.

“Biofuels are still not competitive against the cheap petrochemistry that’s out there,” said Hamberger, a James K. Billman Jr., M.D., Endowed Professor in the College of Natural Science’s Department of Biochemistry and Molecular Biology, or BMB.

Hamberger is also a co-investigator at the Great Lakes Bioenergy Research Center, or GLBRC, a U.S. Department of Energy-funded Bioenergy Research Center led by the University of Wisconsin–Madison.

GLBRC scientists have long sought ways to extract other high-value products from biomass. Research has shown that poplar can be a viable source of p-aminophenol, which is used to make dyes, adhesives, and other polymers, as well as paracetamol, the active ingredient in Tylenol.

When Hamberger joined the center in 2015, he suggested going after terpenes, a group of chemical compounds plants use in unique environmental interactions such as attracting pollinators or defending against pests.

“Terpenes are the oldest, largest class of specialized metabolites on the planet,” said Hamberger, who is also a faculty member in MSU’s Molecular Plant Sciences, Genetics and Genome Sciences and Cell and Molecular Biology programs.

“Since they’re important for all sorts of interactions, it’s driven their diversity to a spectacular point where the chemistry out there is just mind blowing.”

Used by humans for millennia, terpenes have been shown to possess anti-inflammatory, anti-microbial, anti-cancer and anti-bacterial properties, and are key components in flavorings, cosmetics and perfumes just to name a few applications.

Bibik, Hamberger and their collaborators were targeting a terpene called squalene, an organic compound widely used in cosmetic products and a crucial component in vaccines.

Today, most squalene comes from shark liver — in fact, the name of the chemical even originates from the Latin word for shark, squalus.

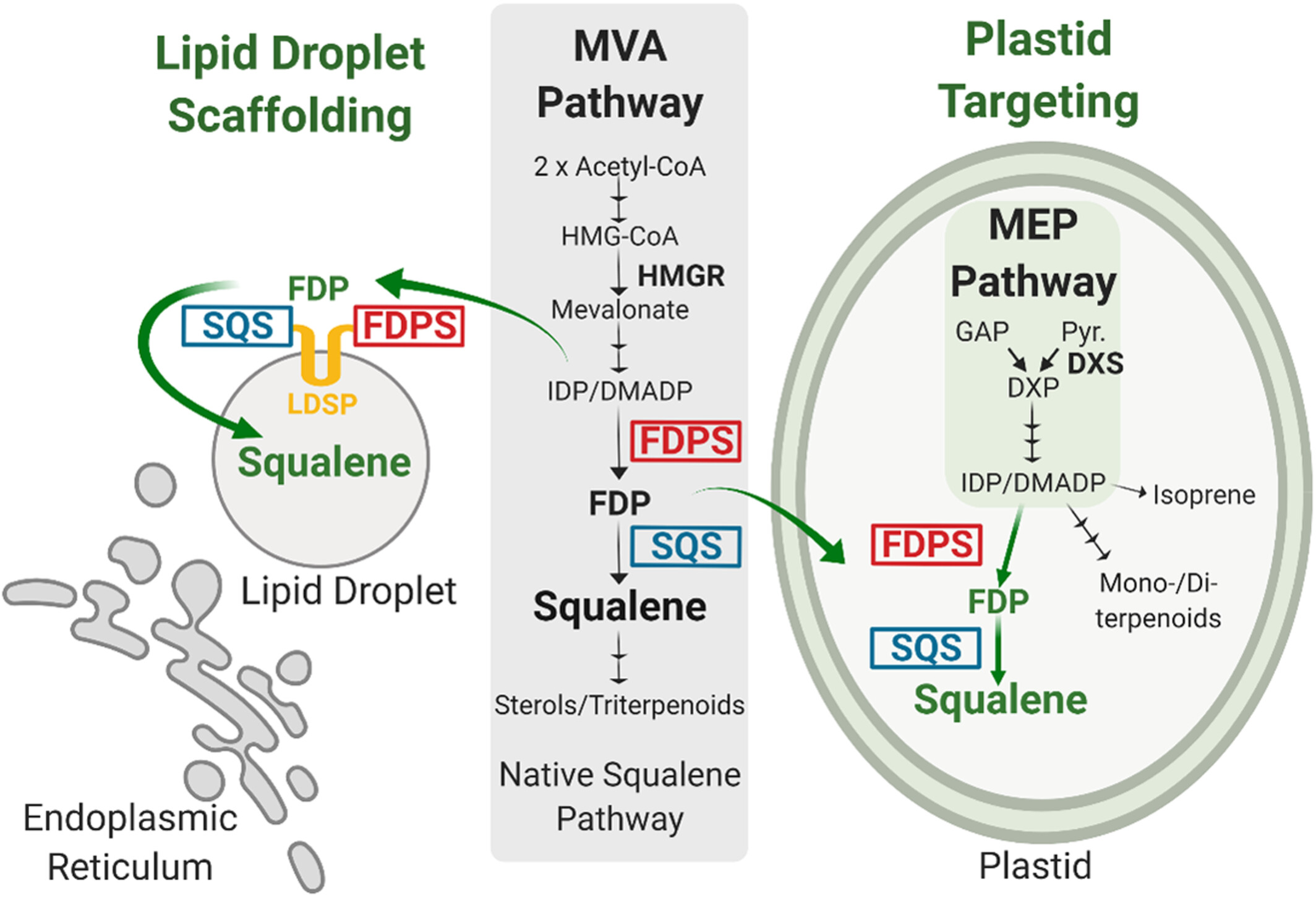

During the project, the team engineered poplars to produce squalene along two distinct chemical pathways.

One pathway utilized the gel-like substance known as cytosol found in the center of cells, while another sought to produce squalene in chloroplasts, the organelles responsible for photosynthesis.

“By diverting carbon away from regular metabolism to make specialized chemicals in unique poplar tissues and droplets, Björn and his team are employing a highly innovative strategy to turn trees into biological factories,” said Professor Shawn Mansfield of the University of British Columbia, an expert on poplar transformation and a collaborator on the latest paper.

“It’s exciting to be part of this highly novel and forward-thinking project.”

While the cytosol pathway was discovered to interfere with poplar root formation, the chloroplast route resulted in the production of 0.63 milligrams per gram of squalene in leaves.

With this promising result, it was time for what Hamberger called a “reality check.”

Looking to upgrade

Working with Christos Maravelias, a professor of chemical and biological engineering at Princeton University, the team next performed an analysis to determine the minimum sales price their poplar-produced squalene would need to be sold at to break even.

The researchers found that number to be $144 per kilogram. Shark-derived squalene comes in at $40 per kilogram.

"If you want to sell a green product to a customer, it can’t only be green, it needs to be affordable,” Hamberger said.

“Luckily, there are several ways to boost the value. One way is increasing overall production, and the other brings us to the cool world of perfumes and another marine animal product — ambergris.”

Produced in the digestive system of sperm whales, ambergris is a valuable fixative in perfumes that prolong scents.

Hamberger said it should be possible to “upgrade” squalene to ambrein, another high-value terpene that makes up ambergris. Scientists have already demonstrated that bacteria can be engineered to produce ambrein, paving the way for further investigation into how poplars could do the same.

Furthermore, another MSU collaborator on the paper, Tom Sharkey, showed that poplars engineered to produce squalene emit less of a gas that indirectly contributes to the greenhouse effect.

“Jake, Björn and their colleagues are working on a method with perhaps the greatest promise to make specialty chemicals and fuel for when only liquid fuel will do, such as jet airplane travel,” said Sharkey, a University Distinguished Professor in BMB. Sharkey is also affiliated with the MSU-Department of Energy Plant Research Laboratory and the Plant Resilience Institute.

With these collective findings, the researchers have broken new ground in the quest to transform poplars into an even more attractive source of biofuels and valuable compounds.

For Bibik, who’s now a senior scientist at the biotechnology company MelaTech, the team’s findings are ultimately another step toward utilizing our planet’s biochemical diversity to address some of its greatest challenges.

“I think this work contributes to a growing foundation that’s necessary to be able to translate plant engineering and terpenoid research into meaningful biotechnologies.”